Missing All Hardware

When I picked up this printer it was missing all the hardware (screws and washers), half of the tools (hex key and wrench), a calibration tool, the IEC power cord, all paperwork, and the SD card.

The biggest problem was the hardware.

I made my way over to the Anycubic Kobra Neo Wiki where I found the assembly instructions which, thankfully, included the entire packing list. I needed:

- M3x8 (4)

- M4x6 (2)

- M4x16 (2)

- M5x25 (2)

- M5x45 (2)

- M5 spring washer (4)

These should all be socket hex head screws - and these are all available at Home Depot (so was the IEC cable). So I stopped by and about $15 later I had what I needed. Returning home, I performed the assembly and was able to power on the printer.

Connecting via USB

Since I did not have the SD card, I wanted to connect via USB. The printer has a USB-C port but it cannot read a USB drive from it - it seems it can only be used for external control.

I went back to the wiki and found the CH341 driver which I installed on my printer control computer (I have a dedicated mini computer for printer control to keep random software off my personal computer and isolated from the rest of the network).

After installing, I was able to see that it was using COM4 (you can see this in Device Manager in windows - look at the COM ports for the one with CH341 in the name) and now I would connect via Cura and Pronterface.

With this done I sent a test print … and it was horrible.

Printhead way too high (Z offset adjustment)

I should have taken a picture of how bad this was - but you’ll just have to imagine it. The first print was just strings of glop dropped from about 1.5-2mm above the bed. I was printing a 50x50x0.20 test print and it looked like I was just running the extruder randomly while playing with the X/Y controls.

Given my other printer is a P1S, I haven’t actually had to deal with this before so I did a little reading to understand that the problem was Z axis height. This is where the missing SD card is a bit of a pain. Anycubic includes a Z-axis adjustment process in the manual but it requires some pre-loaded gcode on the card. Since I didn’t have that, and they don’t link it on the wiki, I basically tried to recreate the process by hand.

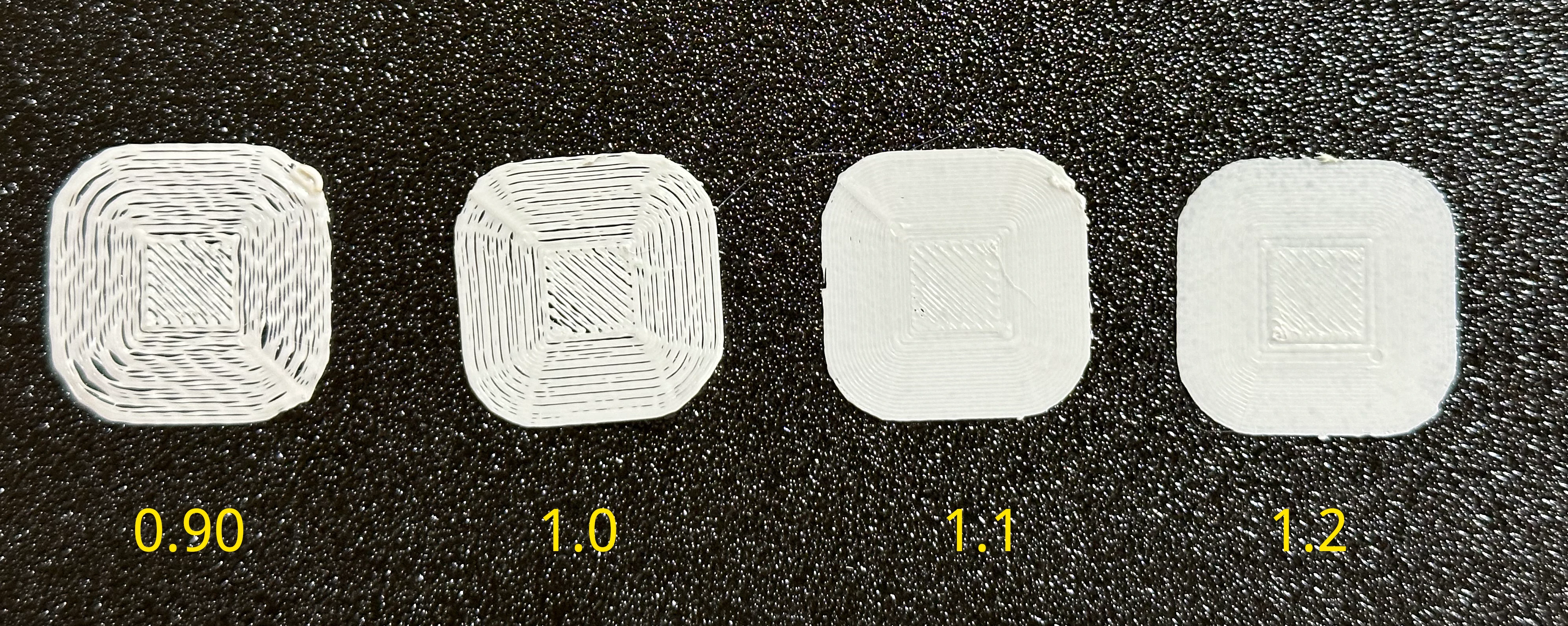

Since the default of 0 was way too high, I started by going to -0.90 and doing 10x10mm test prints at 0.9, 1.0, 1.1, and 1.2. The results were this:

After this I fiddle a bit more and finally ended on -1.14 as my height adjustment and for now it’s fine - I’ll move on to the next steps.

Filament extruding at wrong speed (E-step calibration)

While doing some test prints I noticed there was some under extrusion going on - you can see it above in the z-axis adjustment section.

I decided to do an e-step adjustment to make sure the right amount of filament is coming out. To do this, I followed the process described at all3dp.com.

The following was all done in Pronterface connected to the printer via USB.

- Send the M503 command to get the settings - this returned (among many other things) this information:

echo:; Steps per unit:

echo: M92 X80.00 Y80.00 Z400.00 E390.00

So we have 390 e-steps per mm of filament.

-

Use a ruler and sharpie to add a line to the filament exactly 120mm above the print head.

-

Send the following:

M83;

M18 S60;

M109 T0 R200;

G1 E100 F100;

G4 S90;

M104 S0;

Now, this is where things didn’t work. The printer returned an error on the line G1 E100 F100; complaining that the values were out of range.

So I used the UI to set the extrude length to 100, the speed to 100 (this is mm per minute), and then hit the extrude button manually - and that worked fine.

- Measure and calculate the new value

With that done I measured from the top of print head to my line (it was drawn at 120 but I only sent 100), and found there was a 30mm gap. So it only sent 90 of the 100 I asked for.

Since we saw earlier that there are 390 e-steps per mm - it did exactly 39,000 steps (390 * 100). But it acted like it only did 35100 (390 * 90). So we can now divide 39000 / 90 and we get 433.3.

- Update the setting

To update the setting I simply send the following gcode:

M92 E433.3

M500

That set the new value to 433.3 and then saved it.

- Verify

I re-ran the extrusion test by marking the filament at 120mm and then extruding 100mm and this time when I meausured, it was right at 20mm remaining - so I asked for 100 and I got 100.

FYI - Updating the firmware resets Z-axis and e-steps

I updated the firmware from 1.2.8 to 1.3.3 and noticed immediately that z axis was reset to 0 but it took a little more poking to realize that e-steps were also reset from 433 to 390 causing significant under extrusion.

Just something to keep in mind when you update.